Florida Roofing Underlayment Requirements (2025 Update)

Your roof is designed to protect your home from the elements, and in a state like Florida, where the weather can be particularly challenging, it’s crucial to ensure that your roofing system is built to withstand the unique climate conditions.

One essential component of a robust and resilient roof is the underlayment. In this blog post, we’ll explore:

- What roof underlayment is and what it does

- The weather conditions that affect roofs in Florida

- The specific Florida roofing underlayment requirements

Don’t waste your time trying to understand the Florida building code! Instead, let us make understanding underlayment requirements simple!

Florida Roofing Underlayment Requirements

In Florida, roofing underlayment is required by the Florida Building Code (FBC) as a secondary water barrier beneath all roof coverings — including shingles, tile, and metal systems. The specific requirements vary depending on your location, roof type, and local wind zone classification.

At a minimum, all roofing systems in Florida must include:

- An approved underlayment such as #30 felt, synthetic sheets, or self-adhered membranes

- Installation that follows FBC guidelines, including proper overlap, fastening, and sealing

- Compliance with relevant ASTM standards (e.g., ASTM D226, ASTM D4869, or ASTM D1970)

- Additional reinforcements — like sealed roof decks and high-temp membranes — in High-Velocity Hurricane Zones (HVHZ) such as Miami-Dade and Broward counties

Whether you’re a homeowner or contractor, meeting these requirements is essential for passing inspection, maintaining warranty coverage, and qualifying for wind mitigation insurance discounts. The rest of this guide breaks down exactly what’s required and how to choose the right system for your property.

What Is Underlayment, and What Does It Do?

Underlayment is a layer of material that is installed beneath the roofing shingles or other roofing materials. Its primary purpose is to provide an extra layer of protection to your roof by serving several key functions:

- Water Resistance: Underlayment acts as a waterproof barrier, preventing water from infiltrating your roof and causing damage to your home’s structure. This is particularly important in Florida, where heavy rainfall and frequent storms are common.

- Moisture Management: Underlayment helps manage moisture that may accumulate on your roof, whether from rain, condensation, or other sources. It helps channel water away from vulnerable areas and reduces the risk of mold and rot.

- Temperature Regulation: Underlayment can provide some degree of insulation, helping to regulate the temperature in your attic space. In Florida’s hot and humid climate, this can be especially valuable for energy efficiency.

- Protection Against Wind-Driven Rain: In hurricane-prone Florida, wind-driven rain can pose a significant threat to your roof’s integrity. Underlayment helps prevent water intrusion, even during high winds.

- Secondary Barrier: Underlayment serves as a secondary layer of protection in case of shingle or roofing material damage. It helps keep your home watertight until repairs can be made.

5 Types of Roof Underlayment for Florida Homes

When it comes to underlayment for your roof in Florida, there are several types to choose from, each with its own advantages and suitability for specific situations. Here are some common types of underlayment materials used in the sunshine state:

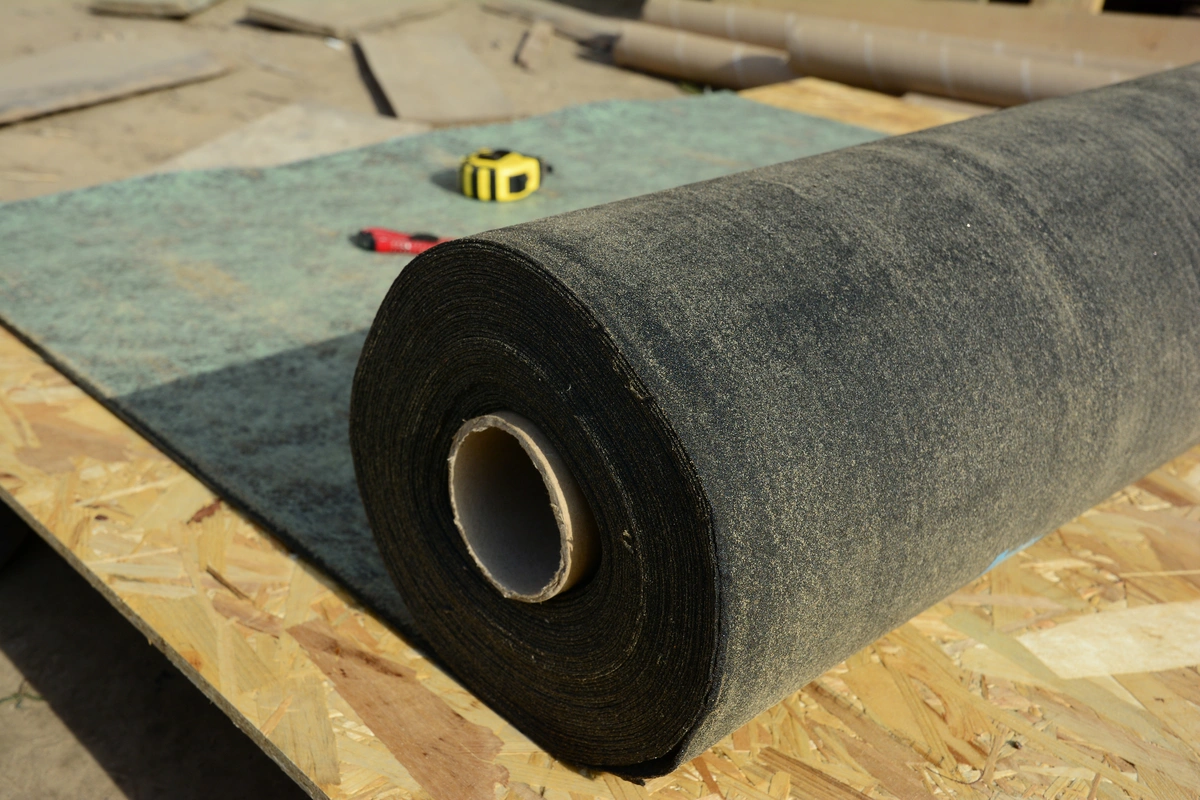

1) Asphalt-Saturated Felt (ASF) or Roofing Felt:

Asphalt-saturated felt, also known as roofing felt or tar paper, is a traditional underlayment material. It is made from organic or fiberglass mat saturated with asphalt and coated with a fine mineral finish.

Best for: Asphalt shingle roofs in non-HVHZ areas

Pros:

- Affordable and widely available

- Meets basic FBC requirements

- Easy to install for standard applications

Cons:

- Can wrinkle under prolonged moisture or heat

- Tears easily under wind stress

- Poor UV resistance if exposed for long periods

2) Synthetic Underlayment:

Synthetic underlayment is gaining popularity in Florida and elsewhere due to its superior performance characteristics. Made from materials like polyethylene or polypropylene, synthetic underlayment is lightweight, durable, and highly resistant to moisture. It also boasts excellent UV resistance.

Best for: Shingle and metal roofs across all zones

Pros:

- Lightweight and durable

- Excellent UV resistance (30–180 days exposure)

- Slip-resistant surface for safer installation

- Available in FBC-compliant variations

Cons:

- Can be costlier than felt (though longer-lasting)

- Wide variation in quality — must verify FL Product Approval

3) Rubberized Asphalt / Self-Adhered Membrane

Rubberized asphalt underlayment combines the flexibility of rubber with the durability of asphalt. It provides excellent waterproofing and is highly resistant to extreme weather conditions, making it a good choice for Florida’s climate.

This type of underlayment adheres well to the roof deck, reducing the risk of wind-driven rain infiltration. It also offers good thermal insulation and UV resistance.

Best for: Tile, metal, or flat roofs in HVHZ (e.g., Miami-Dade, Broward)

Pros:

- Fully adhered to roof deck for a watertight seal

- Self-seals around nails and fasteners

- Meets ASTM D1970 — required in hurricane zones

- High wind and water resistance

Cons:

- More expensive than felt or synthetic

- Requires clean, dry surfaces for proper adhesion

- Can be difficult to reposition during install

4) Hybrid “Tag & Stick” Systems

These use a mechanically fastened base sheet combined with a peel-and-stick top layer.

Best for: Tile roofs in HVHZ or any high-wind area

Pros:

- Easier and faster to install than full peel-and-stick

- Patchable and repair-friendly

- Meets uplift resistance and sealed deck requirements in HVHZ

Cons:

- Requires trained installers for code-compliant performance

Limited to specific manufacturer systems

5) High-Temperature Rated Underlayment

High-temperature underlayment is designed to withstand the intense heat that Florida’s climate can generate. It is often used in conjunction with metal roofing systems or in areas with high sun exposure.

Best for: Metal roofs, low-slope applications, high-sun exposure zones

Pros:

- Heat-rated (240°F+) — won’t deform under hot roofing materials

- Ideal for Florida attic conditions

- Compatible with both steep and low-slope roofs

Cons:

- May require specialized installation or pairing with other layers

- Typically more expensive than standard synthetic options

Weather Conditions That Affect Roofs in Florida

Florida’s climate presents unique challenges for roofing systems. Understanding the specific weather conditions can help you appreciate the importance of underlayment in this region:

- Heavy Rainfall: Florida experiences a high amount of rainfall, especially during the summer months. Without proper underlayment, water can seep into your roof and cause extensive damage over time.

- Hurricanes and Tropical Storms: Florida is vulnerable to hurricanes and tropical storms, which can bring not only strong winds but also torrential rain. Underlayment is crucial for protecting your home during these extreme weather events.

- High Humidity: Florida’s humidity levels are consistently high, which can create an environment conducive to mold and rot. Underlayment helps manage moisture and prevent these issues.

- Intense Sunlight: The Sunshine State lives up to its name with plenty of sunshine year-round. UV radiation from the sun can deteriorate roofing materials over time, and underlayment can provide an extra layer of defense against this.

- Temperature Fluctuations: Florida’s temperatures can vary widely, with hot summers and mild winters. Underlayment can help regulate the temperature in your attic, reducing the strain on your HVAC system.

8 Requirements for Underlayment in Florida

Given the unique weather conditions in Florida, there are specific requirements for underlayment to ensure your roof’s durability and longevity:

1) Material Choice

Choose materials that are approved for Florida’s climate and code:

- Asphalt-saturated felt (#30) – cost-effective, code minimum.

- Synthetic underlayment – lightweight, tear-resistant, UV-resistant.

- Self-adhered membranes (ASTM D1970) – required in HVHZ zones like Miami-Dade and Broward.

- Rubberized asphalt – ideal for waterproofing and nail sealing.

✅ Always verify the product has a valid Florida Product Approval (FL#).

2) Water Resistance:

The primary job of underlayment is to keep moisture out — even under heavy rain or wind-driven storms.

- Consider multi-layer options for low-slope or flat roofs.

- Must resist at least 2.5 pounds per square foot of water pressure.

- Should meet ASTM D226 (Type I or II) or ASTM D4869 (Type I–IV) standards.

3) Installation Method:

Proper installation is essential for performance and inspection approval.

- Overlap underlayment by at least 2″ horizontally and 6″ vertically.

- Seal seams with adhesives or manufacturer-approved tape, especially in HVHZ.

- Install drip edge flashing at eaves and gables to direct water away from fascia boards.

📏 These are minimums per FBC Chapter 15 and HVHZ Addendum.

4) Wind Uplift Resistance:

Florida’s frequent tropical storms and hurricanes make uplift protection critical.

- Reinforce the deck (renailing) when re-roofing in HVHZ, per FBC 1515.1.

- Underlayment should be tested for wind uplift resistance, following RAS 115 protocols.

- Self-adhered underlayments perform best by creating a sealed barrier.

5) High-Temperature Performance:

Roofs in Florida must survive extreme attic temperatures — often exceeding 150°F.

- Avoid materials prone to melting or shrinking in the sun.

- Look for products rated for high heat tolerance (240°F or higher).

- Verify classification under ASTM D4869 Class IV or V.

6) UV Resistance:

Delays in roof covering installation can expose underlayment to sun for days or weeks.

- Essential when storm delays or supply chain issues stall roofing jobs.

- Choose underlayment rated for UV exposure (30–180 days) depending on project timeline.

- Synthetic sheets and SA membranes offer extended resistance.

7) Building Code Compliance:

The Florida Building Code is non-negotiable for insurance, inspections, and legal liability.

- FBC updates every few years — contractors should always follow the latest edition.

- Underlayment must be listed with a valid Florida Product Approval Number (e.g., FL12345-R1).

- Confirm approval for the roof slope, region, and material being used.

8) Professional Installation:

Even top-quality materials fail if installed incorrectly.

- Save documentation: it’s required for wind mitigation inspections and insurance discounts.

- Hire a licensed and insured Florida roofing contractor with FBC experience.

- Ensure proper nailing patterns, seam sealing, and ventilation considerations.

Leave It To the Pros at Greentek!

In Florida, where the weather can be both beautiful and challenging, your roof plays a vital role in keeping your home safe and comfortable. Underlayment is an essential component of your roofing system, providing protection against heavy rainfall, hurricanes, humidity, and intense sunlight. To meet Florida’s unique requirements, choose the right underlayment material, ensure proper installation, and adhere to local building codes.

Got a question? Greentek Roofing is here to help. Contact us today to learn how we can provide you a durable roof that is up to code.

FAQs

What type of roof underlayment is required in Florida?

Florida Building Code requires all roofs to have an approved underlayment — typically #30 felt, synthetic sheets, or self-adhered membranes. High-Velocity Hurricane Zones (HVHZ), such as Miami-Dade and Broward, mandate self-adhered underlayment (ASTM D1970) with sealed roof decks.

Is synthetic underlayment better than felt in Florida?

Yes — in most cases. Synthetic underlayment is more durable, tear-resistant, and UV-resistant, making it ideal for Florida’s extreme weather. However, #30 felt may still be acceptable in non-HVHZ areas and for low-budget installations.

How long can roof underlayment be exposed to sunlight in Florida?

Exposure limits vary. Most synthetic underlayments allow for 30 to 180 days of UV exposure. Asphalt felt offers little UV protection and should be covered within a few days. Always check the manufacturer’s specifications.

Can I install roofing underlayment myself in Florida?

While it’s possible, it’s not recommended. Florida’s building code is strict, and incorrect installation can void warranties, fail inspections, or disqualify you from wind mitigation insurance discounts. A licensed contractor is strongly advised.

Can I mix different types of underlayment on one roof?

Generally, no — mixing underlayment types can violate code and void warranties. Florida’s code expects uniform application of approved materials unless specifically engineered and approved by the manufacturer.